PROHUB PORTABLE 2WD AXLE SHAFT CHASSIS DYNAMOMETERS

UNLEASH YOUR VEHICLE’S TRUE POTENTIAL

Take your tuning to the next level with the Mainline Portable ProHub CCS (CAN Control System) Chassis Dynamometers — the ultimate “in-chassis” solution for extreme streetcars and drag machines. Designed for high-performance testing, the ProHub delivers precision, power, and flexibility that bridges the gap between engine dynos and traditional roller chassis dynamometers.

Available in 2000hp and 3000hp models, the ProHub is fast to set up, easy to move, and simple to store — perfect for workshops, garages, or race paddocks. Use it for performance tuning, ignition timing fine-tuning, pre-race preparation, driveline torque checks, clutch evaluation, nitrous testing, and R&D of performance products.

Need more capability later? Portable ProHub models can be upgraded to AWD, giving you the ultimate in testing versatility as your vehicles and projects evolve.

Power. Precision. Portability. That’s the ProHub difference.

NON-COAXIAL DESIGN

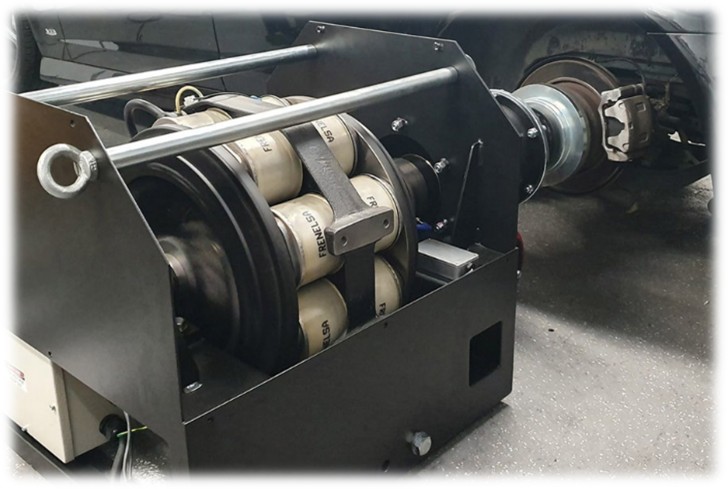

All Mainline ProHub Chassis Dynamometers feature a non-coaxial design. This means the Power Absorption Modules (PAMs) sit flat on the floor, eliminating the need to adjust module angles to match a vehicle’s camber. The result is a faster, simpler setup compared to coaxial designs used by competitors, which can be prone to vibration when modules are misaligned.

Our non-coaxial layout ensures that module alignment relative to the vehicle—vertically or laterally—is not critical. Additionally, ProHub units feature a twin Constant Velocity (CV) joint arrangement within the module extension tubes. The retarders inside the modules are deliberately offset, making it impossible for the connection to the vehicle to be coaxially aligned, further enhancing reliability and stability.

The Portable ProHub 2WD Dynamometer connects directly to the vehicle’s axle hubs using billet steel adapters, eliminating wheel and tyre-related variables. This ensures absolute accuracy and delivers unmatched repeatability from one power run to the next.

Portable ProHub dynamometers can accommodate ±10° of camber and 10° of toe-in/out, making them compatible with both live axle and independent rear suspension (IRS) systems.

Portable ProHub dynamometers can accommodate ±10° of camber and 10° of toe-in/out, making them compatible with both live axle and independent rear suspension (IRS) systems.

HIGH-SPEED OPERATION

All 2WD Portable ProHub CAN Control System (CCS) models are rated for maximum speeds of up to 5,000 axle RPM, or road speeds of up to 400 mph (640 km/h), depending on the vehicle’s gearing. The Power Absorption Modules (PAMS) on the 2,000 hp and 3,000 hp models feature integrated wheel assemblies, allowing them to be easily positioned at the vehicle, accurately aligned, and quickly connected to the axle hubs. Once testing is complete, the PAMS can be conveniently rolled away and stored.

Hub Adapter Sample

CLICK HERE FOR THE LATEST LIST OF AXLE HUB ADAPTERS

CAN CONTROL SYSTEM (CCS)

CAN CONTROL SYSTEM (CCS)

The new Mainline CCS (CAN Control System) represents the next level in sophisticated dynamometer control and precision data acquisition.

Built on a robust and reliable CAN communication network, the CCS connects a central control unit to one or multiple remote CAN control units. This design delivers faster data transfer, quicker control response, and heightened sensitivity to transient or intermittent data changes. Combined with emerging hardware and software innovations, the system meets the exacting standards of the most discerning operators.

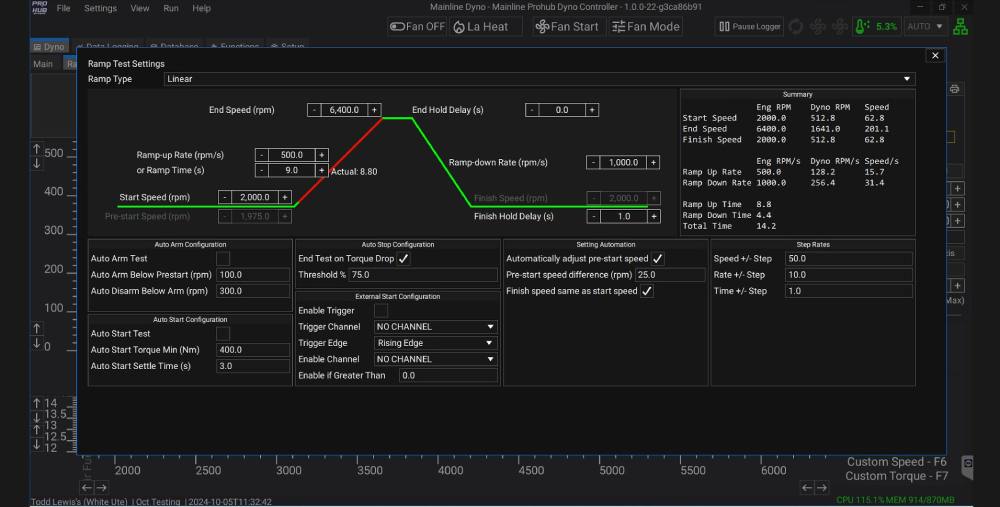

Ramp Test Screen

Data Logging Screen (5 x 10-Minute Continuous Data Loggers )

Data Logging Screen (10-Minute Continuous Data Log)

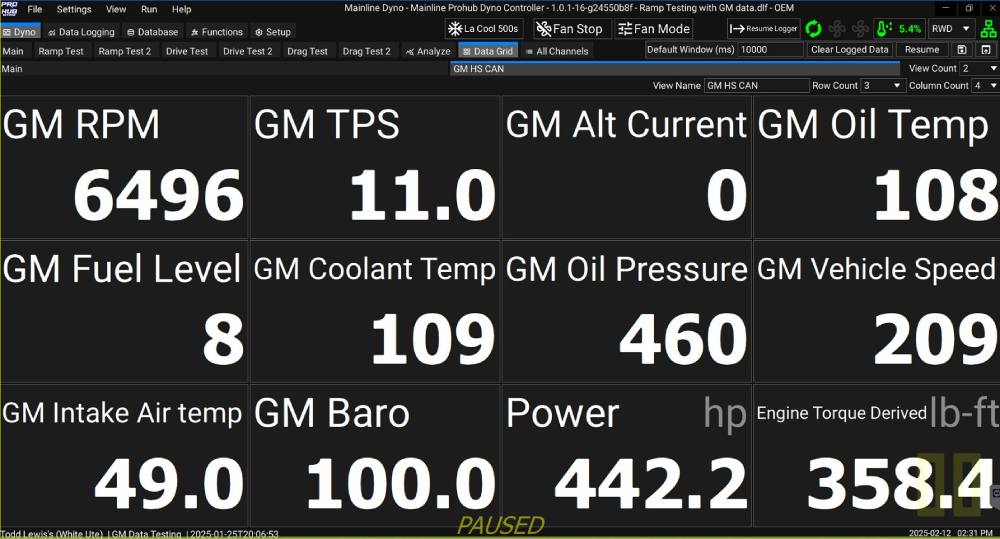

Data Grid Screen

( Showing GM Broadcasted CAN Data)

ADVANCED DYNAMOMETER CONTROL STRATEGIES

The Mainline CCS (CAN Control System) represents the pinnacle of dynamometer control technology, delivering exceptionally fast, accurate, and precise vehicle management during testing. Designed for high-performance applications, it ensures that every run produces reliable, repeatable, and meaningful data.

Eddy Current Brake Mapping: At the heart of the system, Mainline CCS dynamometers feature fully mapped eddy current retarders. Each retarder’s performance is meticulously characterised under all expected operating conditions, allowing the system to implement a fully optimised control strategy. The result is unparalleled precision, consistent braking behaviour, and complete confidence in every test mode, whether for tuning, validation, or performance benchmarking.

Combination Feedforward & PID Control: This advanced control system proactively anticipates changes in demand or torque, reducing the error correction workload typically handled by a traditional PID (proportional, integral, derivative) controller. Simply put, the dynamometer controller focuses on upcoming control challenges rather than reacting to past performance, enabling it to respond quickly to load adjustments and precisely match the performance characteristics of the vehicle under test.

ADVANCED MODES OF OPERATION

The Portable ProHub CCS Chassis Dynamometers offer highly advanced and versatile modes of operation, including:

-

Fixed Speed – Steady state control for consistent speed testing.

-

Fixed Torque – Variable speed with a fixed load or torque control.

-

Drive Test / Road Load Simulation – Simulates real-world conditions based on vehicle weight and aerodynamic coefficients.

-

Linear Ramp Test – Gradually increases load or speed in a linear progression.

-

Non-Linear Ramp Test – Applies a ramp with variable progression for more complex simulations.

-

User-Definable Non-Linear Ramp – Allows custom ramp profiles tailored to specific testing requirements.

-

Drag Strip Run Data Download & Run Simulations – Capture and replay drag strip performance data.

-

Drag Mode – Measures performance over distance or time, considering vehicle weight and aerodynamic coefficients, with staged start and time slip analysis at completion.

-

Torque Balancing / Vectoring – Adjusts torque distribution between left and right sides for precision testing and performance tuning.

Drag Test Staging Lights Start & Time Slip at Completion

Non-Linear Ramp Test Setup Screen

Linear Ramp Test Setup Screen

Drive Test (Non-Linear Setup Screen

(Road Load Ramp Test – Suited for Boosted Vehicle Applications / Acceleration Curves)

KEY FEATURES

Mainline CAN Control System (CCS) Dynamometer – Windows Operating Software

Testing & Simulation Features:

-

Road Load, Fixed Load/Torque, Linear and Non-Linear Ramp/Pull Tests

-

Drag Strip Run Time Simulations

-

Fully Loaded Dyno Ramp Pulls – power calculated from measured torque (unlike inertia dynos)

-

Run duration can be maintained with increasing performance levels

-

Maintains engine and driveline thermodynamics

-

Perfect steady-state control – ideal for live ECU tuning applications

-

Stall converter evaluation and mapping tests (converter loss/efficiency)

Data Acquisition & Logging:

-

5 x 10-minute continuous data loggers with pause, resume, review, save, and recall functionality

-

User-configurable CAN inputs and outputs

-

Data grid supporting multiple digital displays (up to 54 simultaneously)

-

Torque and power, plus multiple graph traces plotted live to the screen (“live as you drive”)

-

Graph-over-graph comparison tests (power/torque vs engine RPM)

-

Multiple configurable MATHS channels to create custom calculations

Sensors & Measurement:

-

Digital axle speed sensors and precision load cells fitted to each module

-

Twin-channel AFR/Lambda meter (CAN interfaced)

-

Automatic AFR/Lambda meter heater control (user-definable parameters)

-

Vehicle cooling fan on/off control

-

AFR fuel types configurable: Gasoline, Ethanol, Ethanol-Gasoline, Methanol, Propane, Diesel, Hydrogen, Butane, Nitromethane

-

Twin 7 BAR MAP/boost sensors for pressure drop testing and analysis

Hardware & Modules:

-

High-quality, heavy-duty, visually aesthetic Power Absorption Modules (PAMS)

-

Space-saving design – modules easily moved within the shop or stored when not in use

-

Adjustable length torque reaction stabiliser bar for operational stability and safety

-

Wide vehicle track capability – accommodates wide vehicles and off-road buggies

-

Quality Frenelsa retarders (power absorption units)

-

Maximum speed rating: up to 5000 axle RPM (640 kph / 400 mph, subject to vehicle gearing)

Control & User Interface:

-

Advanced load control strategies – precise, accurate, safe, super responsive, and repeatable

-

Rolling workstation control storage cabinet with boom arm

-

Automatic weather station included (live and continuous vehicle power correction)

-

Wireless keyboard dyno controller – full operation from inside the vehicle

-

Computer control system with Windows 11™ Professional OS standard

Reporting & Analysis:

-

Customer/vehicle performance print reports

STANDARD INCLUSIONS (All Models)

Rolling Workstation Cabinet with Boom Arm

-

Configuration: Left or Right-Hand (confirmed upon order)

-

Displays: Twin 24” LCD color monitors (supports extended desktop modes)

-

Computer: Desktop PC with Windows 11 Pro OS and Solid-State HDD

-

Software: CCS Dynamometer Software Program (Mainline CAN Control System for Windows)

-

Data Channels:

-

Multiple user-definable data channels

-

Multiple user-definable MATH channels

-

-

Connectivity: User-configurable CANBUS interface

-

Control & Input Devices: Wireless trackball, remote keyboard controller

-

Environmental Monitoring: Automatic weather station with automatic power correction to multiple international standards

-

Vehicle Control:

-

On/Off switching for the vehicle cooling fan

-

-

Air: Fuel Measurement Kit: MAINLINE MDLC2 Wide Band Twin Channel Air: Fuel Ratio / Lambda Meter Kit (CAN interfaced)

-

Pressure Sensors:

-

2 x 7 BAR MAP/ Boost sensors

-

-

Engine Monitoring:

-

Engine RPM (derived from axle speed & gear ratio)

-

Engine tachometer input via inductive clamp

-

Engine tachometer input via 0–500 VDC voltage probe

-

-

Accessories:

-

2 x sets of axle hub adapters

-

Workshop signage pack

-

Mainline Dyno merchandise pack

-

SPECIFICATIONS

|

PORTABLE PROHUB (CCS) CAN CONTROL SYSTEM MODELS |

||

| DYNAMOMETER FEATURE | 2000CCS | 3000CCS |

| Power Absorption Modules | 2 | 2 |

| Frenelsa Eddy Current Retarders | 2 | 2 |

| Torque Reaction Arms / Bars (Yellow Adjustable/ Retractable Arms) | 2 | 2 |

| Torque Capacity / Rating | 6500 Nm / 4800 ft-lbs | 9000Nm / 6638 ft-lbs |

| Power Capacity / Rating ( @ 2000 Axle RPM) | 1490 Kw / 2000 hp | 2238 Kw / 3000 hp |

| Maximum Axle Weight Capacity | 2500Kg /5511 Lbs | 2500Kg / 5511 Lbs |

| Maximum Axle Speed | 5000 Axle RPM | 5000 Axle RPM |

| Maximum Vehicle Road Speed (Subject to Vehicle Gearing) | 640 kph / 400 Mph | 640 kph / 400 Mph |

| Minimum Vehicle Wheel Track | Subject to Vehicle | Subject to Vehicle |

| Maximum Vehicle Wheel Track | Subject to Vehicle | Subject to Vehicle |

| Recommended Floorspace Width (Minimum) | 5000 mm / 197 Inches | 5000 mm / 197 Inches |

| Recommended Floorspace Length | Subject to Vehicle Length | Subject to Vehicle Length |

| WORKSTATION / CABINET ASSEMBLY | ||

| Left or Right Hand Configuration | Standard | Standard |

| AWD Ready Cabinet ( Ready for Future Upgrade to AWD Configuration) | Option | Option |

| Workstation Cabinet with Boom Arm | Standard | Standard |

| Vehicle Cooling Fan Control ( On / Off Switching) | Standard | Standard |

| Automatic Vehicle Cooling Fan Control ( Via Variable Frequency Drive Unit - CAN Open Protocol) | Option | Option |

| 24" Twin Monitors ( Extended Desktop Mode) | Standard | Standard |

| Triple 24" Monitors ( Extended Desktop Mode) | Option | Option |

| Quad 24" Monitors ( Extended Desktop Mode) | Option | Option |

| Desktop PC, Win 11 PRO OS (Solid State HDD) | Standard | Standard |

| Wireless Trackball Remote Keyboard Controller | Standard | Standard |

| DYNAMOMETER CONTROL / DATA ACQUISITION SYSTEM | ||

| Main Head Display Module (CAN) - Dynamometer Controller + 2 Remote CAN Modules | Standard | Standard |

| Main Head Display Module (CAN) to Computer Connection (LAN - Gigabit Ethernet) | Standard | Standard |

| 2WD Vehicle Drive Applications | RWD / FWD | RWD / FWD |

| Data Acquisition Module - Multiple CANBUS Interfaces | Standard | Standard |

| Boom Arm DAQ Module | Standard | Standard |

| DATA ACQUISITION SENSOR INPUTS | ||

| Automatic Weather Station (Automatic Power Correction to Multiple International Standards) | Standard | Standard |

| MAINLINE Wide Band Twin Channel Air: Fuel Ratio/ Lambda Meter (Can Interface) | Standard | Standard |

| 2 x MAP / Boost Modules ( 7 BAR Sensors) | Standard | Standard |

| Engine Tachometer Input ( Inductive Clamp) | Standard | Standard |

| Engine Tachometer Input ( 0 - 500VDC Voltage Probe) | Standard | Standard |

| Twin Channel AFR / LAMBDA Meter (CAN Interfaced) | Standard | Standard |

| OPTIONAL VEHICLE COOLING FAN | ||

| Large Rolling 3 Phase Vehicle Cooling Fan -INVERTED BLOWER (380v to 415V 50Hz– 20 AMP) | Option | Option |

| Large Rolling 3 Phase Vehicle Cooling Fan - INVERTED BLOWER (USA 3Ph Specification – 208V, 60Hz- 40 AMP) | Option | Option |

| Vehicle Cooling Fan Housing Assembly INVERTED BLOWER - NO MOTOR (US Single Phase Applications Only) | Option | Option |

| Variable Frequency Drive (VFD) Control Cooling or Cell Fans | Option | Option |

| OPTIONAL ACCESSORIES | ||

| Mainline CAN EGT – 8 Channel Thermocouple Module | Option | Option |

| Vehicle Cooling Fan Control (Via VFD - Variable Frequency Drive- CAN OPEN Protocol) | Option | Option |

| 24" Triple Monitors ( Extended Desktop Mode) | Option | Option |

| 24" Quad Monitors ( Extended Desktop Mode) | Option | Option |

| Mainline EX7 CAN Expander Module (3 Analog Inputs, 4 Digital Inputs) | Option | Option |

| CAN Gateway Hub (Changes ID Address for CAN input devices) | Option | Option |

| SOFTWARE PROGRAMS | ||

| PC Operating System Software (Windows 11 Pro) | Standard | Standard |

| CCS Dynamometer Software Program (Mainline CAN CONTROL SYSTEM for Windows) | Standard | Standard |

| Dynamometer Software Updates | 2 Year Subscription Included | 2 Year Subscription Included |

| Multiple Definable User Channels | Multiple User Channels | Multiple User Channels |

| CANBUS Interface (User Configurable) | 1 x CANBUS (1000k Bit Rate) | 1 x CANBUS (1000k Bit Rate) |

| CAN Input Expander Module ( CAN 2.0 Classic) 2mbps | 3 x Analog Inputs / 4 x Digital Inputs | 3 x Analog Inputs / 4 x Digital Inputs |

| DYNAMOMETER OPERATING MODES | ||

| Fixed Speed Control ( Steady State) | Standard | Standard |

| Fixed Load Control ( Variable Speed - Fixed Torque) | Standard | Standard |

| Linear Ramp Test | Standard | Standard |

| Non-Linear Ramp Test | Standard | Standard |

| User Configurable Non-Linear Ramp Test ( Download Track Drive Shaft Curve Data & Simulate Run on Dyno) | Standard | Standard |

| Drive ( Road Load ) | Standard | Standard |

| Drive Test - Road Load Simulation | Standard | Standard |

| Drag Racing Simulation (Over Time and Distance) | Standard | Standard |

| Torque Balancing (Left to Right) | Standard | Standard |

| CAN CONTROL SYSTEM MAIN SOFTWARE FUNCTIONS | ||

| Main Screen (Fixed Speed - Steady State/ Fixed Load - Fixed Torque / Road Load Simulation) | Standard | Standard |

| Ramp Test Screen (Linear, Non-Linear, User Non-Linear Acceleration Tests, Drag Mode Simulations) | Standard | Standard |

| Ramp Test 2 - Data Logging Screen ( Data Logging Over Engine Speed) | Standard | Standard |

| Drive Test 1 - Non-PID Ramp Test (Non-Linear) | Standard | Standard |

| Drive Test 2 Data Logging Screen ( Road Load Test Over Distance) | Standard | Standard |

| Analyse Screen ( Multiple Channel Data Analysis) | Standard | Standard |

| Drag Test ( Drag Simulation over distance ) ( Staged Lights Start- Time Slip Issued on Test Completion) | Standard | Standard |

| Data Logging Tab Screens ( Data Logging Over Time - 4 Graphs/ Tab / 8 Data Traces/ Graph) | Standard | Standard |

| Data Grid ( Digital Data Display Screen) (10 Rows x 10 Columns Digital Data Displays) | Standard | Standard |

| Background Data Logger ( Multiple 10 Minute Continuous Data Loggers) | Standard | Standard |

| Customer & Vehicle Database | Standard | Standard |

| Load / Save Test Configurations | Standard | Standard |

| Setup / Utilities | Standard | Standard |

| MISCELLANEOUS | ||

| AFR Meter Extended Exhaust Probe | 2 | 2 |

| AFR Meter Restraint Strap | 2 (1 x Short, 1 x Long) | 2 (1 x Short, 1 x Long) |

| Vehicle Earth Strap | 1 | 1 |

| MAINLINE Internal Vinyl Workshop Banner | Standard | Standard |

| MAINLINE Internal Workshop Sign | Standard | Standard |

| MAINLINE External Workshop Sign | Standard | Standard |

| ProHub Vinyl Rope Banner | Standard | Standard |

| MAINLINE Promo Merchandise Pack | Standard | Standard |

| MAINS POWER REQUIREMENTS | ||

| 3PH Voltage (Australia, Europe, Middle East, Asia) | 380 - 415V (50-63A/Phase) | 380 - 415V (50-63A/Phase) |

| 3PH Voltage (USA, Japan, Canada, Philippines, Others) | 208V (80A/Phase) | 208V (80A/Phase) |

| 1PH Voltage (USA, Canada, Japan) | 220V (100A) | 220V (100A) |

| Frequency | 50/60 Hz | 50/60 Hz |

| PRODUCT SUPPORT & WARRANTY | ||

| Tech Support - Phone, Email, Internet | *Lifetime Support(Free) | *Lifetime Support(Free) |

| Manufacturer Warranty Period (Components) | 24 Months | 24 Months |

| Warranty Exclusions | Consumables | Consumables |

Optional Quad Monitors Display

CLICK HERE FOR THE LATEST LIST OF AXLE HUB ADAPTERS

(September 2025)

PRI Trade Show 2024 Release Video