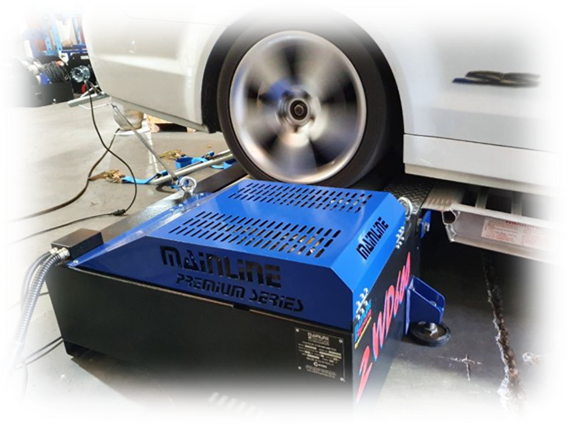

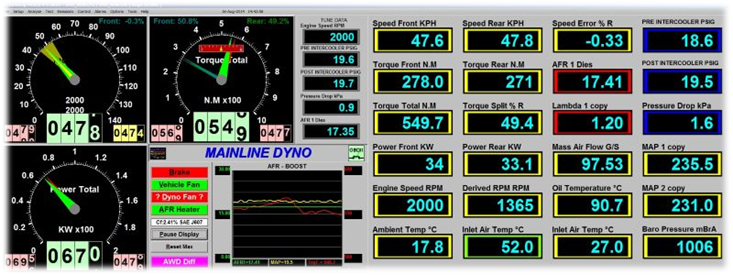

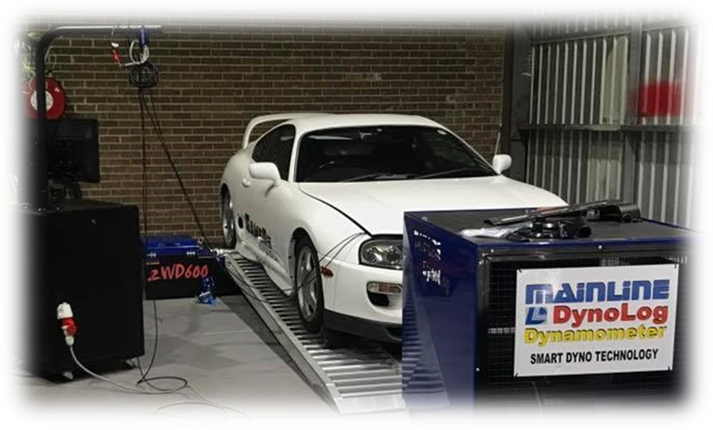

Welcome to the world of the new-generation, truly professional chassis dyno. A Mainline “Premium” model dynamometer is the perfect choice for the astute, professional operators and serious performance tuners who want the most technically advanced and innovative chassis dynamometer available on the market, to ensure their business and technical expertise and reputation progresses to a whole new level.

The Mainline 2WD6000P Premium dyno has innovative vehicle testing concepts, advanced on-screen graphics, and performance-plus characteristics, not available from other dynamometer manufacturers.

Our “Premium” range models are state of the art, and represent the absolute best in dynamometer build quality, precision load control, advanced data acquisition, innovative software functionality and exceptional testing and tuning capabilities.

Fully designed and manufactured in Australia, the 2WD600P chassis dyno will enable you to increase your workshop’s production, attract more customers, generate additional income for your workshop, and substantially add to your bottom line!

Vehicle Applications

- Rear Wheel Drive

- Front Wheel Drive

- Light Commercial

- Hybrids

- EV's

- Motorcycles

Workshop Applications

- General tuning, maintenance & servicing

- Vehicle performance assessments

- Vehicle performance enhancement

- Alternative fueled vehicles

- Live aftermarket ECU tuning

- ECU flash tuning

- Vehicle driveline fault analysis

- Torque transmission & analysis

- Speedometer check / test

- Simulate road load conditions

Business Benefits

- Increase workshop productivity and profits

- Save time simulating speed related faults

- Increase your professional image

- Improve your staff’s competence skills, and increase their job satisfaction

- Increase customer satisfaction with more professional diagnostic and tuning facilities

- Diagnose hard to find problems found during normal road testing

- Test at higher than legal speed limits (< 250 kph) in the safety of your own workshop

- Reduce the risk of on road accidents, or loss of driver’s licence

- Increase customer base by attracting more new customers

- Prove your tuning results, or component manufacturer’s claims

- Promote your business products and services during dyno days

Standard Key Features

- High quality, and visually aesthetic, chassis bed assembly (Fully Upgradeable to AWD / 4WD)

- Above ground or in ground pit installation (Automatic Bi-Directional Operation)

- Quality high capacity Frenelsa eddy current retarder (Power Absorption Unit for Loaded Tests)

- Rugged, accurate and repeatable “S” Beam Load Cell Technology (Rose joint mounted)

- Load cell and retarder cooling fan

- Wide track roller sets (400mm to 2200mm roller track)

- Up to 250 kph / 155 mph test speeds

- 1200Hp – 895kw Power Rating / 1250Ftlbs -1700Nm Torque Rating

- Vehicle traction control & restraint kit (Standard)

- Multi – position traction strap hoops (Suits live axle and IRS systems)

- 12 vehicle anchor points available / 4 repositionable anchor eye bolts

- Premium workstation control & storage cabinet, with twin boom arms

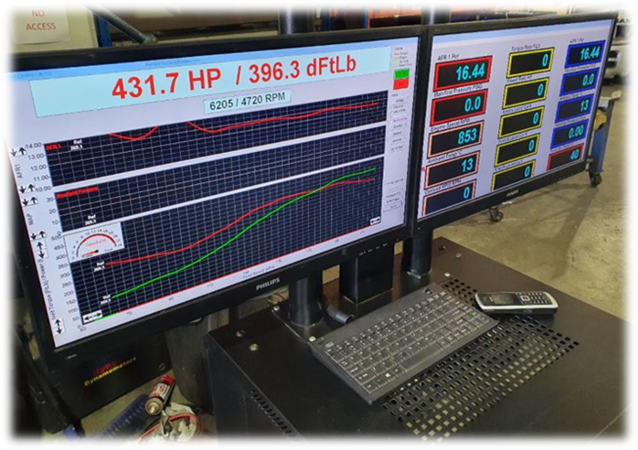

- Twin 24” LCD monitors

- Automatic weather station (Live Environmental Power Correction)

- Automatic vehicle cooling fan control (User definable on / Off control)

- Automatic dyno cooling fan control (User definable on / Off control)

- Automatic AFR / Lambda meter heater control (User definable on / Off control)

- Industry leading dyno controller (Precise, accurate, safe, super responsive & repeatable power results)

- Wireless keyboard dyno controller (All dyno control / operation from within the vehicle)

- Computerised Control System, Solid State Hard Drive, Windows 10™ OS

- Multiple USB Ports, and Network Connection

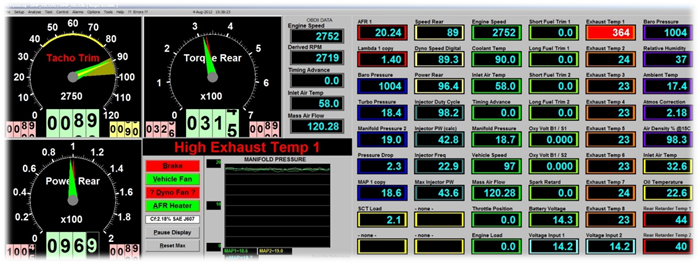

- Mainline DynoLog Premium Pro Software Suite for Windows 10™

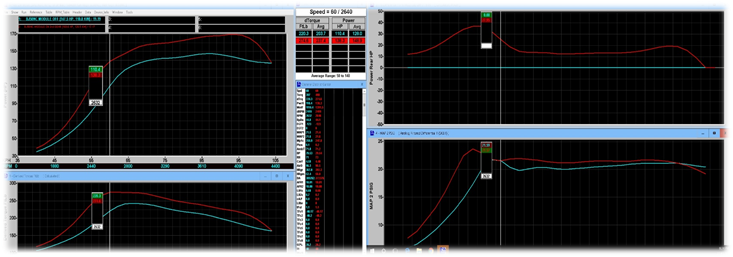

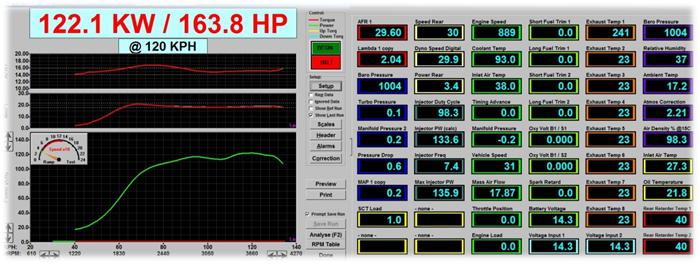

- Steady state and dynamic power acceleration / ramp / pull / tests (100% Repeatable)

- Dynamic graph traces “Live plot to screen” (Live Graph Plots - Up to 3 channels plotted simultaneously during dyno pull

- Graph over Graph (Overlay) comparison tests (Power / Torque graph over Road Speed & RPM)

- Grouped Channels Graph (Multiple Channels Overlay Graph)

- X Y Graph Plot (Y over X Data Plots)

- Dedicated detailed graph data analysis screen (High Resolution Plotting - Fine or Thick Graph Lines)

- Dedicated data analysis screen (Compare up to 12 graphs simultaneously)

- Multiple Digital data displays (Operator configurable/definable) (Up to 97 digital data displays)

- 8 Channel Live Data Chart Recorder (Power, Torque, Motive Force + Other Channels)

- Minimum, Maximum, Live Data Toggle functions + Snapshot Data, & Background Data Logging

- Channel alarms (Operator definable warnings for any dyno data channel)

- Wide band AFR meter kit (Definable – Petrol, Diesel, LPG, CNG, Methanol, Ethanol, E10 & E85)

- Lambda, Lambda Equivalence Ratio, Air: Fuel Ratio, or Fuel: Air Ratio or Custom Stoichiometric selections

- Target Air: Fuel Ratio, & on-screen graphical correction calculator

- Target Fuel Correction Table + Advanced Fuel Correction Calculators

- Custom Fuel AFR (Based on Fuel Specific Gravity & Stoic value)

- Multiple AFR / Lambda meters support (Up to 8 meters connected simultaneously)

- Multiple copy channels (Display AFR and Lambda values simultaneously)

- 200 MATHS channels (Fully user configurable- Add your own calculation channels)

- Twin 7.0 BAR MAP/ Boost sensors (Pressure Drop Testing & Advanced Pressure Delta Analysis)

- Engine Tacho ( Derived) From Roller Speed / Rpm

- Combined Engine RPM Module (Includes Inductive & Voltage Probes, Tacho Trim, Driveline Slip Detection)

- Dedicated Pressure Drop Channel (Digital Display & Graph Trace)

- Torque Optimisation (Torque vs Ignition Timing, AFR, Injector Timing, Cam Timing or TPS)

- Target Boost & Graphical correction calculator

- Test data management system (Log, display, graph, save, recall, edit, reprint saved test results)

- Screenshot Capture (Saves screenshots as an image file) Print report as PDF, BMP or JPG

- Multiple Channel Print Reports

- Customised reports - Insert business logo, or other images on print reports and much more!

- Fully expandable – Hundreds of available options, and supports 400+ external devices

Expandability

Keep your options open…. !

The 2WD600P Premium chassis dynamometer is fully expandable with a multitude of further hardware & software options, and more than 400+ supported third-party plug-in devices. Many of our competitors offer chassis dynamometer systems but offer little regarding a future upgradeability, or further product development. ……

Mainline DynoLog has pioneered development of advanced dynamometer technology and our product research and development is extremely active in improving current products and developing new hardware and software technology to ensure our products remain current with modern vehicle technology. We offer many options AND accessories that are not even available from other dyno manufactures.

The 2WD600P Series chassis dynamometer is fully upgradeable. This system may be upgraded to include any of the following optional devices, sensor inputs or software components:

- Fully field upgradeable to All Wheel Drive (AWD1200P Model)

- Additional AFR Meters (Up to 8 x AFR / Lambda meter inputs currently available)

- Engine RPM inputs – Hardware Tacho (Secondary or primary ignition or any Crank pulse reference source)

- Other Engine RPM Inputs – OBD-II, ECU, RACEPAK or Gas Analyser.

- Tacho Trim – control via logged engine RPM increments (Ideal for steady state engine mapping)

- RPM vs KPH Ratio – Driveline / Convertor/ Clutch Loss Channel (RPM Kit required)

- Additional MAP/ Boost Sensor Inputs (Up to 6x MAP inputs currently available)

- Engine Oil temperature (Engine Dipstick Probe)

- Engine Air inlet temperature (Used for tuning baseline reference – not power correction)

- Exhaust gas or other temperature measurements (Up to16 x EGT inputs available)

- Injector / Component duty cycle module (Duty %) + Hz, Pulse Width, Max PW remaining with RPM Kit)

- 0 to 30 Volt Analogue inputs (Definable – Component Voltage Tests, Device inputs etc.)

- Common Rail Diesel derived fuel pressure measuring

- Fuel and/or Oil Pressure Modules

- Fuel System Analysis - Fuel pressure, twin channel fuel flow, temperature, and ethanol content

- OBD – II Data Logging (SAE & CAN Protocols)

- Multiple Interfaced & Wireless DMM (Multimeters) Supported

- Interfaced optical tacho (Supercharger belt/ pulley RPM slippage, tail shaft RPM / loss etc)

- Interfaced Sound Pressure Meter (dB)

- Interfaced Vibration meter

- Automatic vehicle cooling fan control (Auto or Remote Manual Controlled)

- MATHS channels (200 User definable channels currently available)

- Exclusive “Torque Optimisation “– (Torque over ignition timing, AFR, Camshaft timing, Injector timing, throttle %, or user definable data parameters)

- Exhaust gas analyser interface (35 + gas analyser models currently supported)

- Diesel Opacity or Particulates Meter interface

- ECU Data Logging (MoTeC, Haltech, Autronic, Adaptronic, Vipec, EMS, Link etc…175 + ECU devices supported)

- Hondata, Megasquirt, Racepak & MSD Power Grid integration.

- Pressure Delta Tests (Dedicated pressure drop testing, intercooler loss, exhaust backpressure tests etc)

- Multiple channel data takers and much more!

Accessories – Engine RPM Data Logging Module

This is possibly the most important addition to any Mainline Dyno and the data it can obtain is often underestimated. This hardware module utilises two different type of pickup probes (Voltage Probe or Inductive Clamp) to provide accurate direct engine speed measurements (RPM) from either a voltage probe or an inductive type probe.

The “Voltage Probe” is a wire clip / piercing type clip (3 to 500VDC) that can be connected to various engine trigger sources for engine speed measurement such as:

- Primary Coil Terminal (Coil Negative)

- Coil trigger wire (COP Ignition)

- Injector Trigger Wire

- Cam Angle Sensor

- Crank Angle Sensor

- Tacho Connector

- ECU (Injector, Coil Trigger, CAS, CKS, Tacho)

The “Inductive Clamp” as the name suggests, is clamped over a wire and measures the magnetic “pulses”. This probe can be connected to various engine trigger sources for engine speed measurement as follows:

- Spark Plug Wires

- Primary Coil Wires (Positive or Negative Polarity)

- Coil Trigger or Power Supply

- Injector Trigger Wire

- Common Rail Diesel Injectors (Solenoid Type – Power or Trigger Wires)

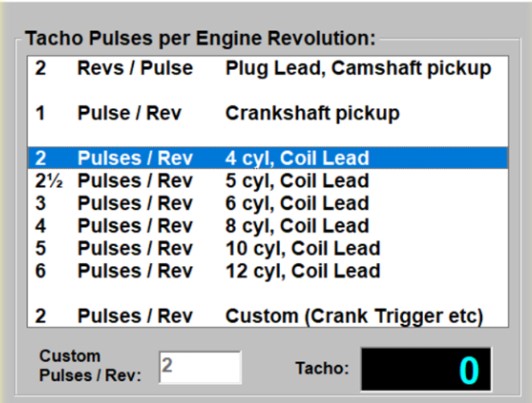

Trigger sources will often have different firing frequencies, so the dynamometer software program provides “Tacho Pickup Pulses per Engine RPM to adjust and calibrate for various sources.

The operator can also select Custom Pulses / Rev”” for any unusual frequency sources, or for solenoid type common rail diesel injectors.

RPM Control Mode – Tacho Trim

The 2WD600P Engine Tachometer / RPM Data Logging Module allows the operator to manually set the desired Engine RPM point as required, and the vehicle will be held at that RPM regardless of throttle position.

The operator may control RPM set points in increments of 50, 100, 150, 200, 250 and 500 RPM steps. The Tacho Trim function makes the mapping of aftermarket programmable Engine Management Systems a breeze.

Just dial up your desired RPM and the dyno will do the rest. The operator can specify the tacho input source (Hardware Tacho, OBD-II, or ECU) and configure the system to allow for manual or automatic transmissions and specify the tacho speed steps and sensitivity. No more continually varying the Dyno Demand/ Road Speed as you progress through the various tuning MAP sites.

Just select your desired RPM and the dyno will do the rest!

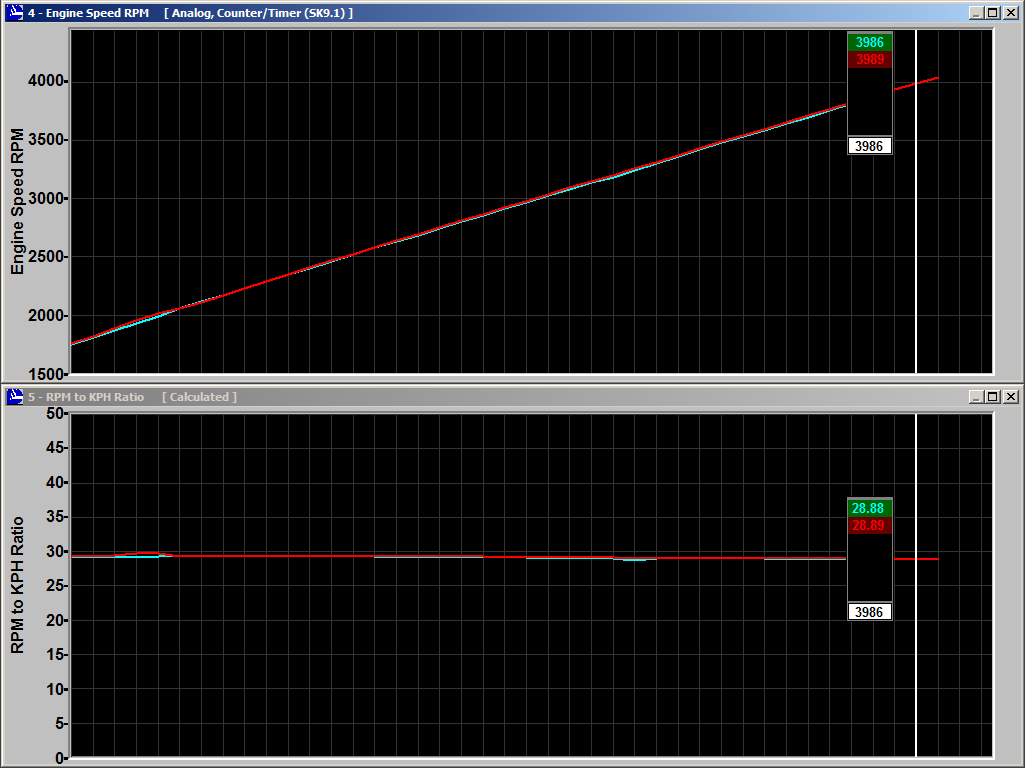

Engine Speed RPM Vs Roller Speed RPM Ratio

Logging engine RPM data over vehicle road speed can also be an invaluable tool for diagnosis driveline problems, clutch slip, torque converter problems, and other torque transmission issues. Essentially the engine speed (RPM) data should appear as a “linear” plotted trace. This would indicate the driveline is functioning correctly whereas a non-linear plot or a sudden flare in the trace line would indicate loss of torque transmission.

Our latest dyno software version has a new channel that graphs “Engine RPM to Vehicle Speed Ratio” which looks at the overall picture and can very quickly identify any loss in torque transmission from the flywheel through to the dyno rollers. The ratio should be generally constant, so as the engine RPM increases, the vehicle's wheels (or axle speed on our ProHub systems) should also increase proportionally.

View RPM / Road Speed Ratio Graphs – Diagnose Vehicle Driveline Loss

(Detect Convertor Lockup/ Slip Trends, Clutch Pressure Plate Slip, Tyre Loss and much more)

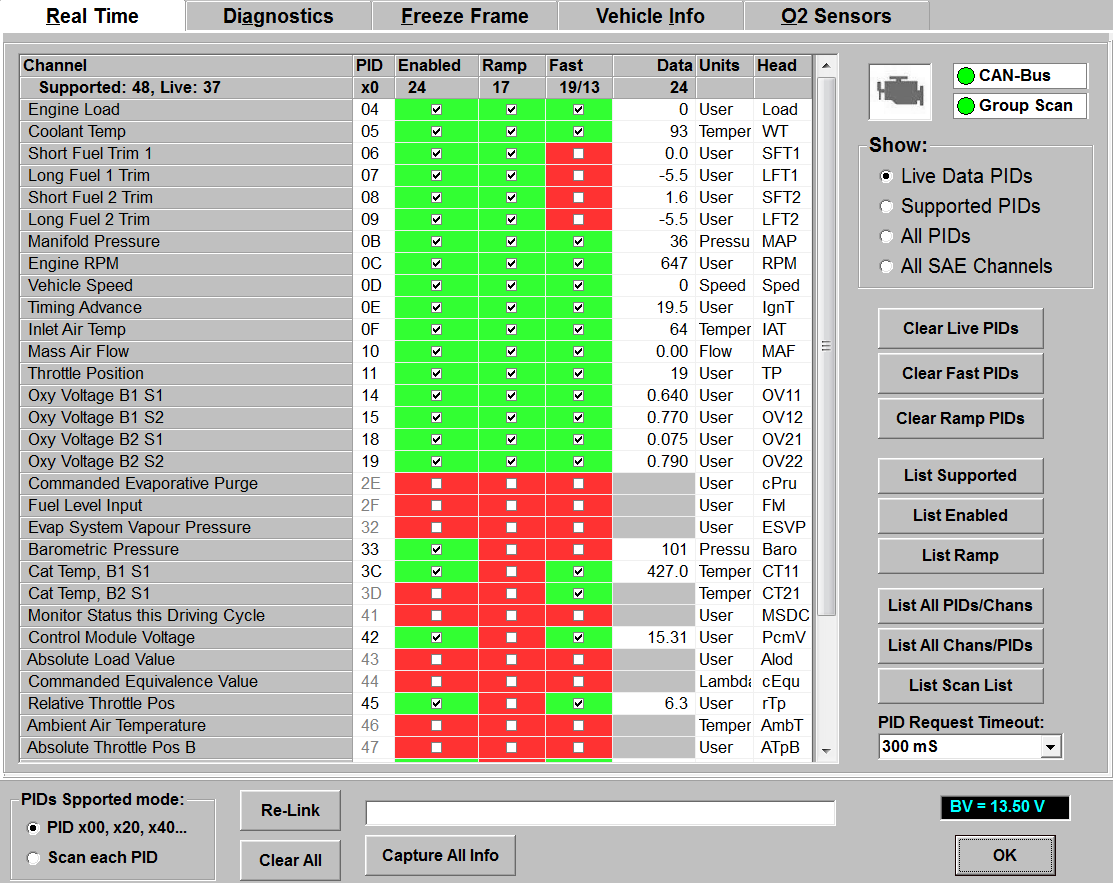

OBD-II Data Logging Module

The 2WD600L Series OBD -II Data Logging module is an enormously powerful tool for extracting data from the vehicle’s ECU and utilising this information for tuning or diagnostic purposes.

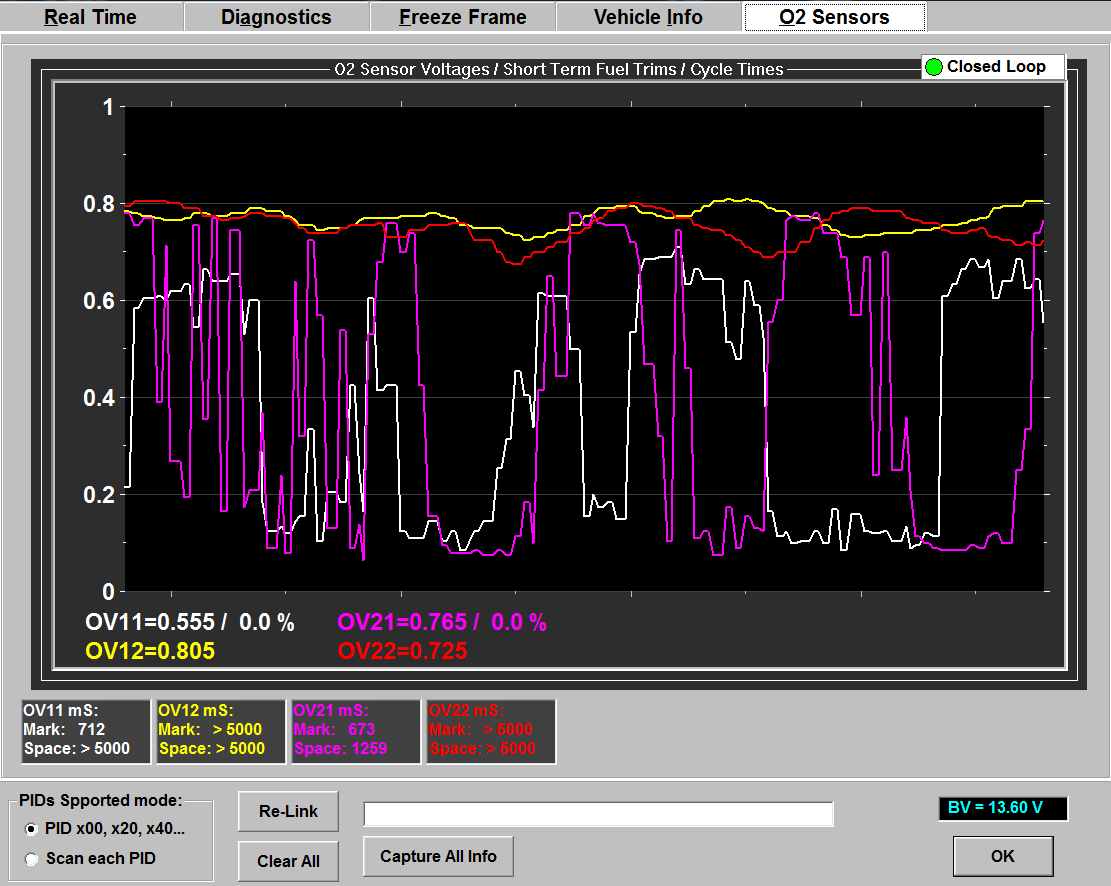

Oxygen Sensors Test – Switching Voltage Traces

Standard Twin Screens – Dual Monitors

Specifications

| CHASSIS BED | |

| Fully Welded Chassis Frame | (All Wheel Drive Ready) |

| Chassis Frame Length | 2886mm / 113.6” |

| Chassis Frame Width | 900mm / 35.4” |

| Chassis Frame Height (Roller Height) | 345mm / 13.58” |

| Chassis Frame Height (Retarder Cover Height) | 455mm / 17.91” |

| Dynamometer Rollers | 4 (2 x Knurled Drive Rollers / 2 x Idler Rollers) |

| Roller Diameter | 218mm / 8.5” |

| Roller Track Minimum | 400mm / 15.7” |

| Roller Track Maximum | 2200mm / 86.6” |

| Eddy Current Retarders | 1 X FRENELSA PAU |

| Maximum Axle Weight Capacity | 2200Kg / 4850 lbs |

| Torque Capacity / Rating - | 1700NM / 1254ft lbs |

| Torque Resolution | 0.01 Nm (0.01 ft-lb) |

| Power Capacity / Rating | 895kw / 1200hp |

| Power Resolution | 0.01 kW (0.01 hp) |

| Recommended Floorspace Width (Minimum) | 4000mm / 157.4” |

| Recommended Floorspace Length (Minimum) | 8 Metres / 27 Ft |

| 3.4 Metre Aluminium Vehicle Ramps (Above Ground Operation) | Option |

| Traction Hoops (Increases Tyre to Roller Traction) | Standard |

| WORKSTATION - CABINET | |

| Deluxe Cabinet with Twin Boom Arms | Standard |

| Dynamometer Control Module | 2WD – RWD / FWD Control System |

| Automatic Vehicle Cooling Fan Control | Standard |

| Automatic Dyno Fan Cooling Fan Control | Standard |

| Automatic AFR Heater Control | Standard |

| 24" Twin Monitors (Extended Desktop Mode) | Standard |

| Desktop PC, Win 10 OS (Solid State HDD) | Standard |

| Wireless Trackball Remote Keyboard Controller | Standard |

| VEHICLE COOLING FAN | |

| Vehicle Cooling Fan (Various Models / Capacities) | Option |

| Automatic vehicle cooling fan control (Auto or Remote Manual Controlled) | Option |

| Variable Speed Control (VSD) Control Cooling or Cell Fans | Option |

| DYNAMOMETER CONTROL - DAQ SYSTEM | |

| Dynamometer PID Controller / Data Acquisition Module | 54 Channel PIDDAQ Module |

| DATA ACQUISITION SENSOR INPUTS | |

| Automatic Weather Station | Standard |

| Wide Band Air: Fuel Ratio/ Lambda Meter | Standard |

| MAP / Boost Module (7 BAR Pressure Sensors) | 2 |

| Pressure Delta Tests (Pressure Drop, Intercooler Loss, Exhaust Backpressure etc) | Standard |

| Additional MAP / Boost Module (7 BAR Pressure Sensors) | Option |

| Roller Speed Sensor | Digital |

| Roller Speed Resolution | 0.01 |

| Force Sensor | Precision Bi-directional S Beam Load Cell |

| Engine RPM Logging Module (Including Engine Inductive & Voltage Input Probes) | Standard |

| Fuel and/or Oil Pressure Module (150 Psi) | Option |

| Fuel Flow Module – Twin Channel Fuel Flow, Fuel Pressure, Fuel Temperature, & Ethanol % | Option |

| 0 to 30 Volt Analogue inputs (Operator Configurable) | Option |

| Interfaced optical tacho (Supercharger belt/ pulley RPM slippage, Tailshaft RPM / Loss) | Option |

| 2 Channel Thermocouple Module | Option |

| 8 Channel Thermocouple Module (CAN Interface) | Option |

| Oil Temperature Dipstick Thermocouple Probe | Option |

| Engine Air Inlet Temperature Thermocouple Probe | Option |

| OBD – II Data Logging (SAE & CAN Protocols) | Option |

| Single or Twin Channel Injector / Component duty cycle module | Option |

| Interfaced & Wireless DMM (Multimeter) | Option |

| Interfaced Vibration meter | Option |

| Interfaced Infrared Temperature Sensor | Option |

| Interfaced 5 Gas Analyser | Option |

| SOFTWARE PROGRAMS | |

| Dynamometer Operating Software Package (Premium Pro) | Premium Level Software Package |

| Dynamometer Software Updates | Lifetime (Original Purchaser Only) |

| MATHS Channels (User Definable) | 200 |

| ECU Data Logging Module | Option |

| ECU Data Logging Module - Single ECU Brand | Option |

| RACEPAK / MSD Power Grid Integration | Option |

| PRODUCT SUPPORT & WARRANTY | |

| Tech Support - Phone; Email; Internet | Lifetime (Original Purchaser Only) |

| Manufacturer Warranty Period (Components Only) | 24 Months |

| Warranty Exclusions | Consumables |

| MISCELLANEOUS | |

| AFR Meter Extended Exhaust Probe | 1 |

| AFR Meter Exhaust Probe Restraint Strap | 2 |

| Vehicle Earth Strap | 1 |

| SIGNAGE & MERCHANISE | |

| MDD Internal Vinyl Workshop Banner | Standard |

| MDD Internal Workshop Sign | Standard |

| MDD External Workshop Sign | Standard |

| POWER REQUIREMENTS | |

| Voltage | 415V / 208 V |

| Phase | 3 |

| AMPS | 32 AMPS |

| Frequency | 50/60 Hz |

| International Voltages (USA, Canada, Middle East, Asia, Europe) | Available |

| MAIN SCREEN SOFTWARE FUNCTIONS | |

| Multiple User Program Configurations | Yes |

| Save System Snapshot | Yes |

| Dedicated Speedometer & Odometer Test & Report | Yes |

| User Defined Maths Channels | 200 |

| Main Screen Analogue Displays (User Configurable) | Yes |

| Gauge Maximum Marker (Resettable Red Max Needle) | Yes |

| Steady State Speed / RPM Set Point Needle | Yes |

| Set Point Digital Display | Yes |

| Set Point Speed Increments (kph) | 0.1, 0.5, 1,5 kph |

| Tacho Trim (Holds @ Selected Engine RPM point/s) | Yes |

| Set Point - Engine RPM Increments | 50 to 500 rpm |

| AWD Speed Error % | Yes |

| AWD Torque Split % | Yes |

| AWD Centre Diff Diagnostic Test | Yes |

| Definable AWD Speed Error Alarms | Yes |

| Screen Data Snapshot (Freeze Screen Data Snapshot) | Yes |

| Main Screen Digital Channel Displays | 100 |

| Second Monitor Screen (Extended Desktop Mode) | Yes |

| Second Monitor Digital Data Displays | < 77 |

| Third Monitor Screen | Option |

| Chart Recorder Displays | Yes |

| Chart Recorder Channels | 8 |

| Chart Recorder Channel Groups | 10 |

| Automatic Weather Station | Yes |

| Ambient Air Temperature | Yes |

| Barometric Pressure Display | Yes |

| Relative Humidity | Yes |

| Atmospheric Correction | Yes |

| Air Density | Yes |

| Humidity Ratio | Yes |

| Air Fuel Ratio | Yes |

| Lambda | Yes |

| Fuel Air Equivalency Factor | Yes |

| Live Power Correction | Yes |

| External Devices (< 400 Supported Devices) | Option |

| External Program Links | Yes |

| Channel Data Monitor Display | Yes |

| W Ramp Test (Light Throttle Diagnostics) | Yes |

| Target Fuel Bar Graphs (> 8 AFR Inputs) | Yes |

| Pressure Delta (Multiple Pressure Drop Test) | Yes |

| Steady State XY Live Graph | Yes |

| Static Snapshot Logging | Yes |

| Background Data Logging | Yes |

| OBD 2 Data Monitor Screen | Option |

| Cylinder Balance Test (< 8 Cyl) | Yes |

| Torque Optimisation - Minimum Timing for Best Torque | Yes |

| Torque Optimisation - Optimal Lambda | Yes |

| Torque Optimisation - Optimal Cam or Injection Timing | Yes |

| Torque Optimisation - Optimal Torque vs Throttle Position | Yes |

| Injector Dead Time Test (Live Data) | Yes |

| 8 Channel Live Data Scan (User Configurable) | Yes |

| Min / Max/ Live Data Capture | Yes |

| Channel Alarms (Visual Warning & Switched Outputs) | Yes |

| Channel Data Statistics Summary | Yes |

| RAMP TEST SCREEN FUNCTIONS | |

| Dynamic Acceleration (Ramp/Pull) Test | Yes |

| Step Test (User Configurable) | Yes |

| Live Power / Torque Graph (Live as you drive) | Yes |

| 3 Channel Live Graph (User Definable Channels) | Yes |

| Test Data Quick View Screen Feature | Yes |

| Test Data Quick View Digital Displays | 10 |

| Definable Ramp Rate (Acceleration Rate) kph/sec | 1 - 40 |

| Ramp up (Acquire Data - Rising Speed) | Yes |

| Ramp Down (Acquire Data - Falling Speed) | Yes |

| Ramp & Down (Acquire Both - Average) | Yes |

| Calculate Engine Acceleration Rate RPM/ sec | Yes |

| Excessive Ramp Rate Warning | Yes |

| Engine RPM Limiter (User Configurable) | Yes |

| Configurable Display Scales | Yes |

| Superimposed Reference Graph Run | Yes |

| Superimposed Last Graph Run | Yes |

| Digital Channel Displays | 7 |

| Digital Channel Groups | 10 |

| Second Monitor Screen | Yes |

| Second Monitor Digital Data Displays | < 77 |

| Third Monitor Screen | Option |

| ANALYSE SCREEN FUNCTIONS | |

| Power Graph | Yes |

| Torque Graph | Yes |

| Motive Force Graph | Yes |

| Derived Torque Graph (Derived from Engine RPM) | Yes |

| Minor Graphs (Graph other Channels) | Yes |

| On Screen Cursor | Yes |

| Statistics @ Cursor | Yes |

| Data Cursor Flybox | Yes |

| Average Results | Yes |

| Maximum Results | Yes |

| Data Difference Graph | Yes |

| Data Difference Percentage Graph | Yes |

| Integral Data (Power under the curve) | Yes |

| X Axis Speed | Yes |

| X Axis Engine RPM | Yes |

| Autoranging Graph Traces | Yes |

| User Definable Fixed Graph Scaling | Yes |

| Total Graph Displays | 12 |

| Data Channels Per Minor Graph | 10 |

| Toggle Multiple Graph Traces | Yes |

| Data Table (Min, Max, Difference, Average) | Yes |

| RPM Table (Advanced Target AFR/ Boost Table) | Yes |

| Data Smoothing (None, Light, Medium, Heavy) | Yes |

| Smoothing Type Moving Average | Yes |

| Smoothing Type - Savitsky - Golay | Yes |

| Average Multiple Runs | Yes |

| Channel Group Graph (Multiple Trace Graph) | Yes |

| XY Graph (Definable X & Y Axis) | Yes |

| EMISSION TESTS | |

| Combustion Analysis | Option |

| Catalytic Convertor Efficiency | Option |

| Western Australia Emission / Sound dB | Option |

| ECE 83 Drive Cycle Simulator | Option |

| IM240 Drive Cycle Simulator | Option |

| FTP Drive Cycle Simulator | Option |

| DT 80 Drive Cycle Simulator | Option |

| Custom Drive Cycle | Option |

| Calibrate Gas Analyser Latency | Option |

| ACTIVE CONTROLS | |

| Brake (30 Second Retarder Brake) | Yes |

| Automatic Vehicle Cooling Fan Control | Yes |

| Automatic AFR Meter Heater Control | Yes |

| Automatic Dyno Cooling Fan/s Control | Yes |

| Auxiliary Fan Control | Option |

| Dyno Cell Fan Control (VSD) | Option |

| Pneumatic Tie Down Pressure Controller | Option |

| AWD Wheelbase Adjustment / Position | Yes |

| AWD Vehicle Wheelbase Database | Yes |

| Warning Strobe Light Activation | Option |

| UTILITIES / TOOLS | |

| Multiple User Program Configurations | Yes |

| Manage Runs Utility | Yes |

| Find Runs (Dyno Run Search) | Yes |

| Backup Data | Yes |

| Export Data | Yes |

| Bulk Export Data | Yes |

| Merge CSV Data File | Yes |

| Engine Calculator | Yes |

| Injector Calculator | Yes |

| Ignition/injection/ Cam Timing Interactive Graphic | Yes |

| Conversion Calculator | Yes |

| Air Flow Calculator | Yes |

| Drag ET Calculator | Yes |

| Ackerman Angle Calculator | Yes |

| General Calculator | Yes |

| Notepad | Yes |

| Basic Paint Program | Yes |

| Gearing Report | Yes |

| Test External Channels | Yes |

| DISPLAY MONITOR SUPPORT | |

| Second Monitor Screen | Yes |

| Second Monitor Screen Graphs | < 77 |

| Third Monitor Screen | Option |

| External Monitor Screen Support | Yes |

| PRINT REPORTS | |

| Graph Power / Torque | Yes |

| Graph Power/ Motive Force | Yes |

| Show Overlay Run | Yes |

| Show Minor Graph | Yes |

| Print Large Graph (Landscape Format) | Yes |

| Show Annotations (Graph Comments) | Yes |

| Insert Image on Graph | Yes |

| Show Business Logo | Yes |

| Graph Other Channels (Any Dyno Channel) | Yes |

| Print XY Graph | Yes |

| Print Speedometer & Odometer Report | Yes |

| Print Channel Groups | Yes |

| Print Multiple Trace Large Graph | Yes |

| Print Multiple Channel Plots | Yes |

| Print Difference Data Table | Yes |

| Print Difference Graph | Yes |

| Print Test Conditions | Yes |

| Insert Memo | Yes |

| Print Graph PDF Format | Yes |

| Save Graph Jpg Format | Yes |

| Save Graph BMP Format | Yes |

| SOFTWARE CHANNEL LIST | |

| Speed Rear | Yes |

| Speed Front | Yes |

| Speed Total | Yes |

| Speed Error | Yes |

| Torque Front | Yes |

| Torque Rear | Yes |

| Torque Total | Yes |

| Torque Split % | Yes |

| Derived Torque | Yes |

| Motive Force Rear | Yes |

| Motive Force Front | Yes |

| Motive Force Total | Yes |

| Power Front | Yes |

| Power Rear | Yes |

| Power Total | Yes |

| Engine Speed (Secondary or Primary Ignition Source) | Yes |

| Derived Engine RPM (Derived from Wheel speed) | Yes |

| Engine Speed ECU | Yes |

| Engine Speed OBD - II | Yes |

| Exhaust Temperature 1 | Yes |

| Exhaust Temperature 2 | Yes |

| Exhaust Temperature 3 | Yes |

| Exhaust Temperature 4 | Yes |

| Exhaust Temperature 5 | Yes |

| Exhaust Temperature 6 | Yes |

| Exhaust Temperature 7 | Yes |

| Exhaust Temperature 8 | Yes |

| Exhaust Temperature 9 | Yes |

| Exhaust Temperature 10 | Yes |

| Exhaust Temperature 11 | Yes |

| Exhaust Temperature 12 | Yes |

| Exhaust Temperature 13 | Yes |

| Exhaust Temperature 14 | Yes |

| Exhaust Temperature 15 | Yes |

| Exhaust Temperature 16 | Yes |

| Manifold Pressure 1 | Yes |

| Manifold Pressure 2 | Yes |

| Manifold Pressure 3 | Yes |

| Manifold Pressure 4 | Yes |

| Manifold Pressure 5 | Yes |

| Manifold Pressure 6 | Yes |

| Manifold Pressure Copy 1 | Yes |

| Manifold Pressure Copy 2 | Yes |

| Pressure Drop (Pressure Delta) | Yes |

| Intercooler Loss | Yes |

| MAP / Fuel Delta | Yes |

| Lambda / Air: Fuel Ratio 1 | Yes |

| Lambda / Air: Fuel Ratio 2 | Yes |

| Lambda / Air: Fuel Ratio 3 | Yes |

| Lambda / Air: Fuel Ratio 4 | Yes |

| Lambda / Air: Fuel Ratio 5 | Yes |

| Lambda / Air: Fuel Ratio 6 | Yes |

| Lambda / Air: Fuel Ratio 7 | Yes |

| Lambda / Air: Fuel Ratio 8 | Yes |

| Lambda / AFR Copy 1 | Yes |

| Lambda / AFR Copy 2 | Yes |

| Lambda (Brettschneider Equation) | Yes |

| Fuel Air Equivalency Factor | Yes |

| Target Fuel Correction 1 | Yes |

| Target Fuel Correction 2 | Yes |

| Target Fuel Correction 3 | Yes |

| Target Fuel Correction 4 | Yes |

| Target Fuel Correction 5 | Yes |

| Target Fuel Correction 6 | Yes |

| Target Fuel Correction 7 | Yes |

| Target Fuel Correction 8 | Yes |

| Target Boost Correction 1 | Yes |

| Target Boost Correction 2 | Yes |

| Ambient Temperature | Yes |

| Engine Inlet Air Temperature | Yes |

| Retarder Temperature 1 | Yes |

| Retarder Temperature 2 | Yes |

| Retarder Temperature 3 | Yes |

| Barometric Pressure | Yes |

| Relative Humidity | Yes |

| Air Density % | Yes |

| Humidity Ratio (Grains/lb.) | Yes |

| Humidity Ratio (Grams/kg) | Yes |

| Oil Pressure | Yes |

| Oil Temperature | Yes |

| Fuel Pressure | Yes |

| Fuel Flow | Yes |

| Fuel Temperature | Yes |

| Fuel Ethanol Content | Yes |

| Percent Fuel Return (Of Used Fuel) | Yes |

| Percent Fuel Return (Of Total) | Yes |

| Fuel Consumption MPG | Yes |

| Mass Air Flow (Calculated) | Yes |

| SCT Load (Ford SCT Tuning Program Users) | Yes |

| Specific Air Consumption | Yes |

| Specific Fuel Consumption | Yes |

| Combustion Efficiency | Yes |

| Thermal Efficiency | Yes |

| Air Volume Flow (Fuel Flow x AFR) | Yes |

| Fuel Grams / Kilometre | Yes |

| Air Grams / Kilometre | Yes |

| Total Air Fuel / Kilometre | Yes |

| Injector Duty Cycle 1 | Yes |

| Injector Duty Cycle 2 | Yes |

| Injector Frequency | Yes |

| Injector Pulse Width | Yes |

| Injector Maximum Remaining Pulse Width | Yes |

| Exhaust Gas Analyser (Multiple Channels) | Yes |

| ECU Data Logging (Multiple Channels) | Yes |

| OBD-II Data (Multiple Channels) | Yes |

| EFILive Flashscan V2 Interface (Multiple Channels) | Yes |

| Analogue Voltage Input 1 | Yes |

| Analogue Voltage Input 2 | Yes |

| Analogue Voltage Input 3 | Yes |

| Analogue Voltage Input 4 | Yes |

| Common Rail Diesel Derived Fuel Pressure | Yes |

| Tyre Loss | Yes |

| Wheel Power | Yes |

| Torque Convertor Slip | Yes |

| Torque Convertor K Factor | Yes |

| Torque Convertor Efficiency | Yes |

| Piston Speed Average | Yes |

| Piston Speed Maximum | Yes |

| Piston Acceleration | Yes |

| ADDITIONAL SOFTWARE PROGRAMS | |

| Emissions Testing Module / Drive Cycle Simulator | Option |

| ECU Data Logging Module (All Supported ECU Types) | Option |

| ECU Data Logging Module (Individual ECU Licence) | Option |

| RS 232/485/CAN Bus Software Interface | Option |

| External Devices (400 + Supported Devices) | Option |